Contents

- 1 Polyaluminum Chloride (PAC) in Water Treatment: Benefits, Drawbacks, Applications, and How to Choose High-Quality PAC

- 2 What Is Polyaluminum Chloride (PAC)?

- 3 Why PAC Is Widely Used in Water Treatment

- 4 Potential Drawbacks and Safety Considerations

- 5 How to Choose High-Quality Polyaluminum Chloride (PAC)

- 6 Why Choosing a Trusted Supplier Matters

- 7 Conclusion: PAC Remains a Critical Solution for Modern Water Treatment

Polyaluminum Chloride (PAC) in Water Treatment: Benefits, Drawbacks, Applications, and How to Choose High-Quality PAC

Polyaluminum chloride (PAC) is one of the most widely used inorganic coagulants in the global water treatment industry. Whether in municipal drinking water treatment, sewage purification, industrial wastewater management, or effluent treatment plants (ETP), PAC plays a critical role in improving water quality and ensuring water safety. Its fast coagulation speed, strong adsorption capacity, and ability to produce dense and easily settleable flocs have made it a preferred option for water treatment professionals worldwide.

As water treatment standards continue to rise and environmental protection requirements become stricter, understanding PAC—its properties, advantages, potential drawbacks, and selection criteria—has become increasingly important for plant operators, engineers, buyers, and distributors. This article provides a comprehensive overview of PAC to help you make informed purchasing and application decisions.

What Is Polyaluminum Chloride (PAC)?

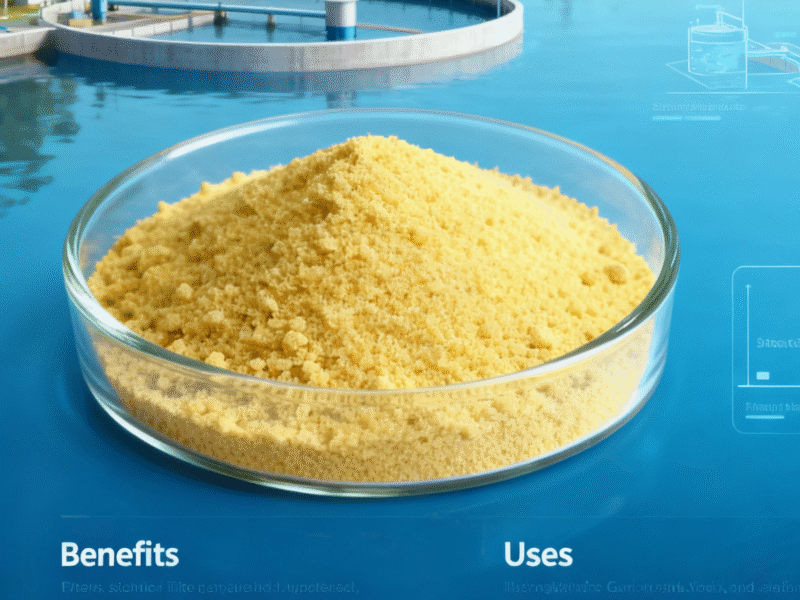

Polyaluminum chloride (PAC) is a highly efficient water treatment coagulant manufactured from aluminum-based raw materials. It is typically available in powder, granular, or liquid form, with colors ranging from light yellow to white, depending on the purity level and application grade. PAC is known for its high basicity, strong bridging and adsorption capabilities, and ability to function effectively in a wide range of pH conditions.

Why PAC Is Widely Used in Water Treatment

1. Rapid and Effective Coagulation

PAC destabilizes and aggregates fine particles quickly, forming large, dense flocs that settle easily. This leads to faster clarification and significantly improved water quality. Numerous studies published on ScienceDirect demonstrate PAC’s superior coagulation performance compared to traditional alum.

(ScienceDirect source: https://www.sciencedirect.com/topics/chemistry/polyaluminium-chloride)

2. Improved Water Quality

By reducing turbidity, removing suspended solids, and lowering organic content, PAC helps ensure that treated water meets strict quality standards. This is especially critical for urban drinking water, industrial process water, and wastewater discharge.

3. Lower Treatment Cost

Because PAC has a high coagulation efficiency, water treatment facilities often use a lower dosage compared to traditional coagulants such as alum (aluminum sulfate). Lower usage reduces overall treatment cost and chemicals consumption.

4. Wide Application Range

PAC works well under various temperature and pH conditions, making it suitable for:

- Drinking water treatment

- Municipal sewage treatment

- Industrial wastewater (textile, chemical, mining, etc.)

- Paper mills

- Swimming pools

- Desalination plants

- Sludge dewatering

Its versatility makes it one of the most reliable and adaptable coagulants available.

5. Reduced Sludge Generation

Compared to many alternatives, PAC generates less sludge, lowering the cost and environmental impact of sludge treatment and disposal.

Potential Drawbacks and Safety Considerations

Although PAC is highly effective, it is important to understand certain limitations and safety concerns.

1. Residual Aluminum in Treated Water

Prolonged or excessive use of PAC can lead to high residual aluminum concentrations. Excessive aluminum in drinking water may pose risks to human health if not monitored properly. This issue highlights the importance of:

- Choosing high-purity PAC

- Applying the correct dosage

- Monitoring residual aluminum levels

2. Environmental Impact During Production

The production of PAC can generate waste and emissions. Sustainable sourcing is important, as emphasized by UN Water, which highlights the need for environmentally responsible water management practices.

(UN Water: https://www.unwater.org/)

3. Need for Proper Storage

PAC is hygroscopic, meaning it absorbs moisture easily. Improper storage can lead to clumping, reduced efficiency, and potential contamination.

4. Overdose May Cause Water Turbidity

Using more PAC than needed may actually worsen water turbidity or increase sludge production. Proper jar testing and dose optimization are necessary for achieving the best results.

How to Choose High-Quality Polyaluminum Chloride (PAC)

Selecting the right PAC supplier and product is essential to ensure effective water treatment performance. Below are key factors to consider when purchasing PAC:

1. Supplier Reputation & Reliability

Working with a trustworthy and experienced PAC supplier ensures:

- Stable product quality

- Reliable supply capacity

- Professional technical support

- Compliance with international standards

Reputable suppliers typically offer COA (Certificate of Analysis) and third-party test reports.

2. Appearance of the Product

High-grade PAC usually has:

- Uniform color (light yellow, yellow, or white depending on grade)

- No visible impurities

- No hard clumps (indicating proper storage and freshness)

Any signs of discoloration or caking may indicate quality issues.

3. Purity and Basicity Level

Higher purity PAC contains fewer impurities and provides better efficiency in coagulation. The basicity (degree of polymerization) determines performance in different water conditions.

Common PAC grades include:

- Industrial grade

- Trinkwassergüte

- High purity white PAC

For drinking water applications, always select drinking water grade PAC compliant with relevant safety standards.

4. Aluminum Content (Al₂O₃ Percentage)

PAC quality is often assessed by its Al₂O₃ content. Higher Al₂O₃ levels generally indicate stronger coagulation performance.

Typical ranges:

- 28%–30% Al₂O₃ (standard grade)

- ≥ 30% Al₂O₃ (high-purity grade)

5. pH Adaptability

Different types of PAC perform differently under various pH conditions. Choose a PAC type that matches the water source characteristics. For example, some PAC grades perform better in acidic water, while others are optimized for neutral water conditions.

6. Price vs. Quality

Price is an important factor, but should not be the sole criterion.

- Very low prices may indicate inferior raw materials or poor production processes.

- Very high prices do not automatically guarantee better performance.

A balanced evaluation of quality, performance, technical support, and price is essential.

Why Choosing a Trusted Supplier Matters

A reliable PAC supplier ensures consistent quality and provides:

- Technical guidance for dosage and application

- Customized formulations based on water characteristics

- On-time delivery

- Transparent quality documentation

These factors are critical to achieving stable water treatment results and long-term operational efficiency.

Conclusion: PAC Remains a Critical Solution for Modern Water Treatment

Polyaluminum chloride (PAC) continues to be one of the most important coagulants in municipal, industrial, and wastewater treatment. Its strong flocculation efficiency, wide adaptability, and cost-effectiveness make it an indispensable chemical for ensuring clean and safe water.

However, choosing the right PAC product and supplier is essential to maximize performance while minimizing risks such as residual aluminum and environmental impact. By considering factors such as purity, appearance, pH adaptability, supplier reputation, and price, buyers can make informed decisions that ensure excellent water treatment results.

If you need professional guidance, technical support, or want to purchase high-quality PAC, feel free to contact wasserpflegechem.de. We are committed to providing reliable products and expert solutions for all your water treatment needs.

Last Updated on 2025-11-18 by system