Contents

- 0.1 SHMP in Industrial Water Treatment

- 0.2 The Fight Against Scaling: SHMP as a Potent Scale Inhibitor

- 0.3 Guarding Against Corrosion: SHMP’s Protective Layer

- 0.4 Beyond Scaling and Corrosion: Additional Benefits

- 0.5 Conclusion: A Cornerstone of Effective Water Management

- 1 Are you experiencing persistent scaling or corrosion issues in your industrial water systems? Exploring the precise application of SHMP could be the solution you’re looking for.

- 2 SHMP in Industrial Water Treatment: A Comprehensive Solution from Scaling to Corrosion

SHMP in Industrial Water Treatment

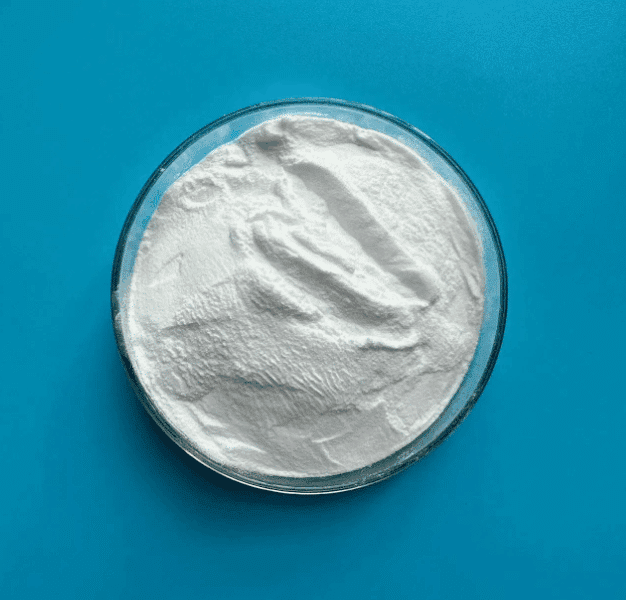

In the vast and complex world of industrial operations, water is an indispensable resource. However, the very water that fuels processes can also be their undoing, leading to costly issues like scaling and corrosion. These problems can significantly reduce equipment efficiency, increase maintenance costs, and even lead to system failure. Fortunately, a powerful ally in combating these challenges is Sodium Hexametaphosphate.

SHMP, a versatile polyphosphate, plays a pivotal role in industrial water treatment due to its unique chemical properties. Let’s delve into its core functions and how it offers a comprehensive solution to these common industrial water woes.

The Fight Against Scaling: SHMP as a Potent Scale Inhibitor

Scaling, the accumulation of mineral deposits (like calcium carbonate, magnesium carbonate, and silica) on pipes and equipment surfaces, is a persistent headache in many industrial settings. These deposits act as insulating layers, impeding heat transfer in boilers and heat exchangers, and restricting water flow in pipelines. The result? Reduced efficiency and increased energy consumption.

This is where SHMP shines as an effective scale inhibitor. Its mechanism involves several key actions:

- Chelation (Sequestration): SHMP has a strong ability to chelate (bind) with multivalent metal ions such as calcium (Ca²⁺) and magnesium (Mg²⁺). By forming soluble complexes with these ions, it prevents them from precipitating out of the water and forming hard scales. Think of SHMP as a tiny chemical “net” that captures these mineral ions, keeping them suspended in the water rather than allowing them to stick to surfaces.

- Threshold Inhibition: Even at very low concentrations, SHMP can interfere with the crystal growth of scale-forming minerals. It adsorbs onto the surface of nascent scale crystals, distorting their growth and preventing them from forming a coherent, hard deposit. This “threshold effect” means a little SHMP goes a long way.

- Dispersion: Sodium Hexametaphosphate can also act as a dispersant, keeping fine particulate matter, including any existing scale particles, suspended in the water, preventing their agglomeration and subsequent deposition.

Guarding Against Corrosion: SHMP’s Protective Layer

Corrosion, the degradation of materials due to chemical reactions with their environment, is another significant threat to industrial infrastructure. It can lead to leaks, structural damage, and costly replacements. While SHMP is primarily known for scale inhibition, it also offers valuable corrosion control benefits.

SHMP contributes to corrosion prevention in two main ways:

- Protective Film Formation: In some water systems, SHMP can contribute to the formation of a thin, protective film on metal surfaces. This film acts as a barrier, preventing direct contact between the corrosive elements in the water and the metal, thereby slowing down the corrosion process.

- Sequestering Corrosive Ions: By chelating certain metal ions (like iron, which can contribute to corrosion products), SHMP helps to maintain water quality and reduce the potential for corrosive reactions.

Beyond Scaling and Corrosion: Additional Benefits

The utility of SHMP extends beyond these core functions:

- pH Buffering: SHMP can help to stabilize the pH of industrial water, which is crucial for optimizing the performance of other treatment chemicals and minimizing the risk of corrosion.

- Sludge Conditioning: In certain applications, SHMP can help to condition sludges, making them easier to handle and dispose of.

Conclusion: A Cornerstone of Effective Water Management

In industrial water treatment, maintaining system integrity and efficiency is paramount. Sodium Hexametaphosphate (SHMP) stands out as a fundamental component in achieving this goal. By effectively inhibiting scale formation and contributing to corrosion control, it not only extends the lifespan of equipment and reduces maintenance burdens but also significantly enhances operational efficiency and reduces energy consumption. For industries relying on consistent, high-quality water, SHMP is more than just a chemical additive; it’s a comprehensive solution that underpins robust and reliable water management strategies.

Are you experiencing persistent scaling or corrosion issues in your industrial water systems? Exploring the precise application of SHMP could be the solution you’re looking for.

SHMP in Industrial Water Treatment: A Comprehensive Solution from Scaling to Corrosion

Industrial water systems are the lifeblood of many operations, from power generation and manufacturing to chemical processing. Yet, these critical systems constantly battle two persistent enemies: scaling and corrosion. Both can lead to costly downtime, reduced efficiency, increased maintenance, and ultimately, premature equipment failure.

Enter Sodium Hexametaphosphate, a highly effective and versatile chemical compound that stands as a cornerstone in industrial water treatment. Often overlooked by the general public, SHMP plays a pivotal role in maintaining the health and longevity of industrial water infrastructure.

The Twin Threats: Scaling and Corrosion

Before diving into SHMP’s capabilities, let’s understand the challenges it addresses:

- Scaling: This occurs when minerals dissolved in water, primarily calcium and magnesium, precipitate out of solution and form hard, insulating layers on pipe walls, heat exchangers, and other equipment surfaces. This buildup, known as scale, drastically reduces heat transfer efficiency, restricts water flow, and can even lead to blockages.

- Corrosion: This is the deterioration of metal surfaces due to chemical reactions with their environment, most commonly oxygen and other dissolved gases in water. Corrosion weakens equipment, leads to leaks, and introduces undesirable metallic ions into the water stream, affecting product quality or discharge regulations.

How Sodium Hexametaphosphate Provides a Comprehensive Solution

SHMP, a polyphosphate, tackles both scaling and corrosion through its remarkable chemical properties:

1. Potent Scale Inhibition (Antiscalant)

SHMP excels as an antiscalant due to its powerful sequestering and dispersing abilities.

- Sequestering: SHMP has a strong affinity for problematic metal ions like calcium (), magnesium (), and iron (). It forms stable, soluble complexes with these ions, effectively “tying them up” and preventing them from precipitating out of solution to form scale. This keeps the minerals suspended in the water, preventing their accumulation on surfaces.

- Dispersing: Beyond sequestration, SHMP also acts as a dispersant. It helps to keep any fine particulate matter or nascent scale crystals dispersed in the water, preventing them from agglomerating and adhering to surfaces. This ensures that even if some crystallization begins, the particles remain small and can be easily flushed away.

This dual action of sequestration and dispersion makes SHMP particularly effective in preventing the formation of common scales such as calcium carbonate (), calcium sulfate (), and iron oxides.

2. Effective Corrosion Control (Corrosion Inhibitor)

While primarily known for its antiscalant properties, SHMP also contributes significantly to corrosion inhibition.

- Protective Film Formation: SHMP can form a thin, protective film on metal surfaces. This film acts as a barrier, isolating the metal from corrosive agents like dissolved oxygen and other aggressive ions in the water. This passivation layer significantly slows down the corrosion process.

- Metal Ion Sequestration: By sequestering metal ions, SHMP also reduces their availability to participate in corrosion reactions, further contributing to the overall anti-corrosive effect. This is particularly relevant for preventing issues like copper and lead leaching in plumbing systems.

Key Applications of Sodium Hexametaphosphate in Industrial Water Treatment

The versatility of SHMP makes it indispensable across a range of industrial sectors:

- Cooling Water Systems: From cooling towers to closed-loop systems, SHMP prevents scaling and corrosion on heat exchange surfaces, maintaining optimal heat transfer efficiency and extending equipment lifespan.

- Boiler Water Treatment: In boilers, SHMP is crucial for preventing scale formation on boiler tubes, which can severely impair heat transfer and lead to overheating and tube failure. It also helps protect the boiler itself from corrosive attack.

- Reverse Osmosis (RO) Systems: SHMP is widely used as an antiscalant in RO membranes, preventing mineral fouling and ensuring the efficient and continuous operation of these critical desalination and purification units.

- Industrial Process Water: Across various manufacturing processes, SHMP helps maintain water quality, preventing issues caused by mineral buildup or corrosion that could impact product quality or process efficiency.

- Municipal Water Treatment: Beyond industrial uses, SHMP is also applied in municipal water systems to prevent scale and corrosion in pipelines, reducing infrastructure damage and ensuring consistent water flow to consumers.

Advantages of Using Sodium Hexametaphosphate

- High Efficiency: Effective at relatively low concentrations.

- Cost-Effective: Provides significant return on investment by reducing maintenance, downtime, and equipment replacement costs.

- Versatility: Addresses both scaling and corrosion issues.

- Compatibility: Generally compatible with other common water treatment chemicals.

- Ease of Use: Available in various forms (powder, granular) for easy dissolution and dosing.

Conclusion

In the demanding world of industrial operations, maintaining the integrity and efficiency of water systems is paramount. Sodium Hexametaphosphate stands out as a powerful and indispensable tool, offering a comprehensive solution to the twin threats of scaling and corrosion. By leveraging its unique sequestering and film-forming capabilities, industries can safeguard their valuable assets, enhance operational performance, and ensure the long-term reliability of their water treatment processes.

Do you have specific challenges with scaling or corrosion in your industrial water system? Share your experiences in the comments below!

Reference: Sodium hexametaphosphate

Last Updated on 2025-06-01 by system