Contents

- 1 Differences Between Polyaluminum Ferric Chloride (PAFC) and Polyaluminum Chloride (PAC): A Complete Guide

Differences Between Polyaluminum Ferric Chloride (PAFC) and Polyaluminum Chloride (PAC): A Complete Guide

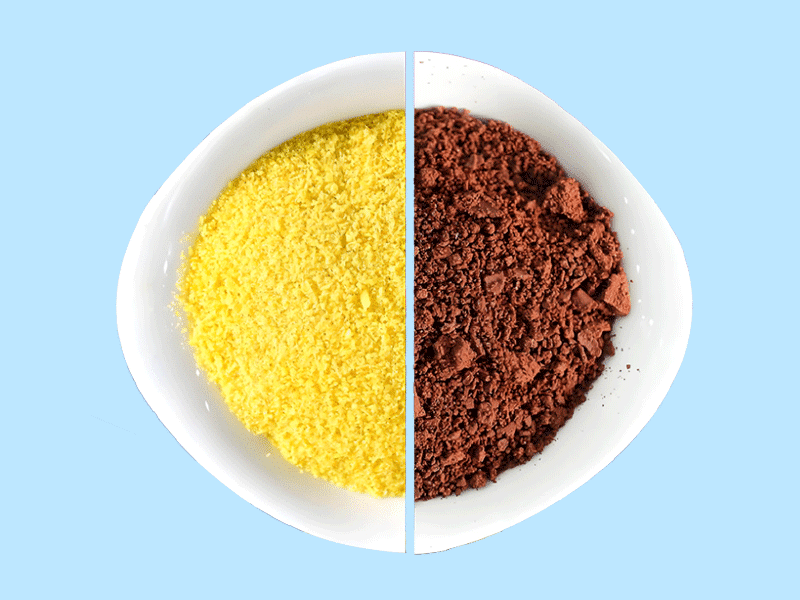

PAFC vs PAC are two of the most commonly used coagulants in water and wastewater treatment, choosing the right coagulant can make the difference between efficient purification and costly inefficiencies. Two of the most widely used inorganic polymer coagulants are Polyaluminum Chloride (PAC) and Polyaluminum Ferric Chloride (PAFC).

Although their names sound similar, they differ significantly in composition, performance, cost, and applications. At WaterCareChem, we are often asked: “Should I use PAC or PAFC for my project?” This guide compares the two, so you can select the most suitable option.

What is Polyaluminum Chloride (PAC)?

Composition and Appearance

-

Main Composition: Pure aluminum salt, with no iron content.

-

外观 Yellow, off-white, or white powder/granules. (White PAC is food-grade and offers the highest purity.)

Raw Materials and Manufacturing

-

Raw Materials:

-

Drinking water grade: aluminum hydroxide powder.

-

Industrial grade: calcium aluminate powder.

-

-

Process: PAC is made by polymerizing aluminum salts, forming strong chains without extra metals.

Core Benefits

-

High Coagulation Capacity: Al³⁺ ions effectively remove turbidity and color.

-

pH Range: Works best between 6–9.

-

Low Corrosiveness: Safe to use, but efficiency may decrease in colder water.

-

Effluent Advantage: Produces soft water, ideal for textile and food-related applications.

Common Applications

-

Drinking water treatment.

-

Industrial water and municipal wastewater.

-

Low-turbidity sources like river or lake water.

What is Polyaluminum Ferric Chloride (PAFC)?

Composition and Appearance

-

Main Composition: Combination of aluminum and iron salts (≈4% iron).

-

外观 Reddish brown or brown powder.

Raw Materials and Manufacturing

-

Raw Materials: Aluminum-calcium powder plus iron compounds (e.g., ferric chloride).

-

Process: Adds an iron-ion introduction step to enhance floc formation and sedimentation.

Core Benefits

-

Synergistic Performance: Aluminum’s adsorption-bridging power combines with iron’s rapid precipitation ability.

-

Stable at Low Temperatures: Works well in cold or fluctuating water conditions.

-

Enhanced Pollutant Removal: Superior at removing heavy metals (Cr⁶⁺), COD, and phosphorus.

-

Dense Flocs: Easier sludge dewatering after treatment.

Common Applications

-

Industrial wastewater only (not for drinking water).

-

High-pollution sources such as steel, paper, and textile wastewater.

-

Water requiring heavy metal and phosphorus removal.

PAFC vs PAC: A Side-by-Side Comparison

| Feature | PAC | PAFC |

|---|---|---|

| Composition | Pure aluminum salt | Aluminum + iron salt (~4% Fe) |

| 外观 | Yellow / off-white / white | Reddish brown |

| Raw Materials | Aluminum hydroxide / calcium aluminate | Aluminum-calcium + ferric salts |

| pH Range | 6–9 | 6–9 (more stable in cold water) |

| Performance | Strong turbidity & color removal | Dense flocs, faster sedimentation, better at heavy metal removal |

| Applications | Drinking water, industrial, municipal | Industrial wastewater only |

| Cost | Higher, especially food-grade PAC | Lower, ideal for large-scale projects |

| Sludge | Moderate | Dense, easier to dewater |

Cost and Dosage Considerations

-

PAC:

-

Cost: Higher, especially white food-grade.

-

Dosage: 1–15 g per ton of water.

-

-

PAFC:

-

Cost: Lower raw material base, cost-effective for large volumes.

-

Dosage: 3–40 g per ton of water, depending on pollution level.

-

How to Choose Between PAC and PAFC

-

Choose PAC if:

-

You need safe drinking water treatment.

-

Effluent softness matters (e.g., textiles, food processing).

-

Source water has low turbidity and stable temperature.

-

-

Choose PAFC if:

-

You are treating highly polluted industrial wastewater.

-

Heavy metal or phosphorus removal is required.

-

Water conditions are cold, fluctuating, or highly variable.

-

Cost-effectiveness is a priority for large-scale operations.

-

Conclusion

Both PAC and PAFC are powerful coagulants, but they serve different needs:

-

PAC is best for drinking water and low-pollution sources, where safety and effluent softness are key.

-

PAFC is ideal for industrial wastewater, offering stronger performance, adaptability, and lower cost.

At WaterCareChem, we provide:

-

PAC and PAFC samples for testing.

-

Small-scale test guidance and technical support.

-

Bulk supply tailored to your water treatment needs.

???? For expert advice or to request product samples, contact WaterCareChem.

Last Updated on 2025-09-26 by system

One thought